Critical insights from two decades of experience to ensure your decommission and demolition projects get executed successfully.

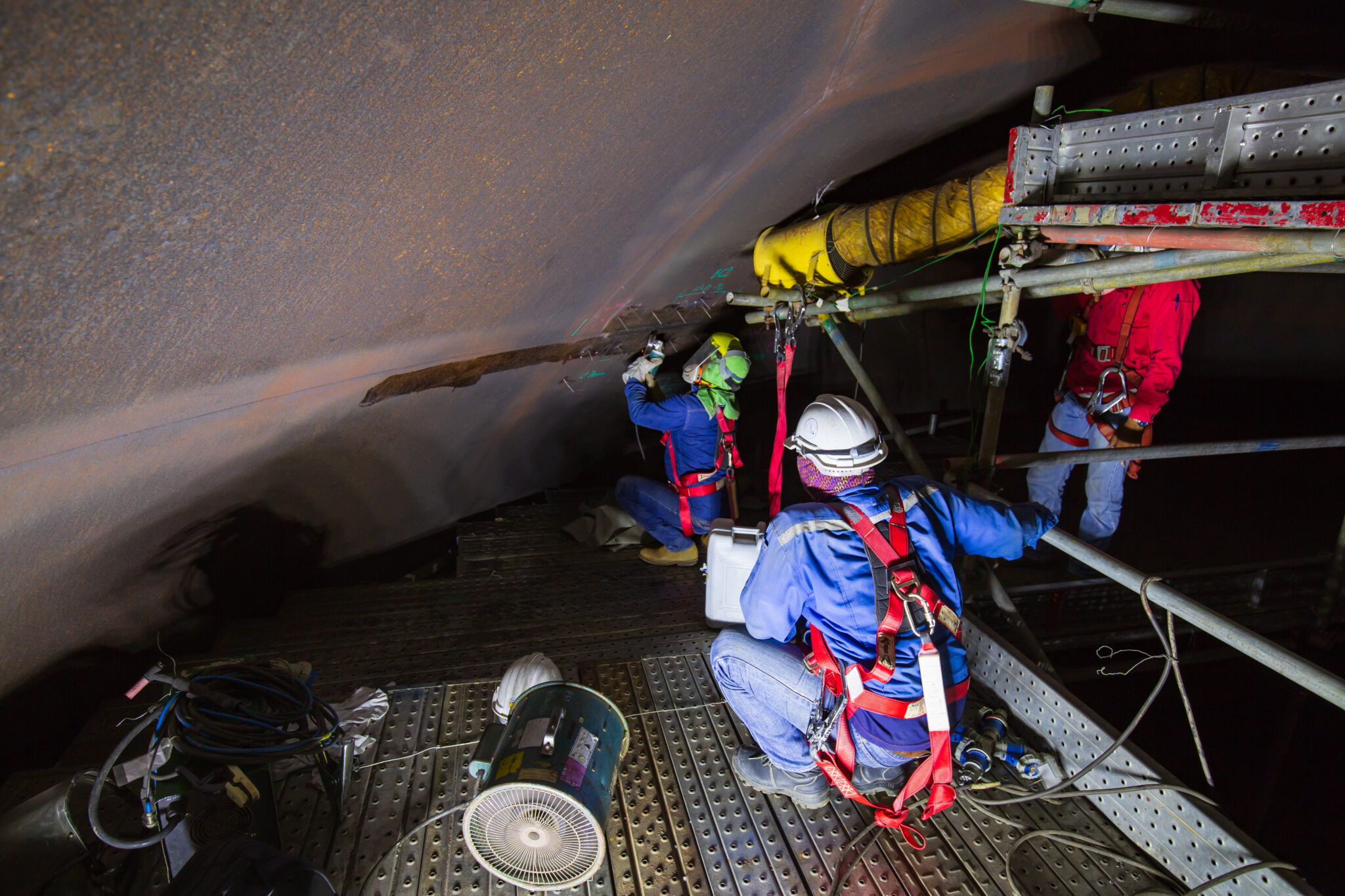

Energy companies across the country have committed to decommissioning and demolishing dozens of coal-burning power plants. These massive, complex projects present both obvious and hidden dangers, making them highly sensitive to safety preparation and compliance regulations.

Project expectations are met through expert due diligence

Planning and executing a coal plant decommissioning (and subsequent demolition) requires knowledge of recognized dangers but also demands preparation for the unknown. That makes it critical to understand the full needs of your project and the appropriate due diligence cannot be underestimated.

Any project of this magnitude needs safety and compliance alignment across the entire job. Your plant decommission project calls for EHS guidance to provide:

- Hazard inspections

- Hazmat removal

- Mediation between various parties involved in the project

- Oversight of contractors through the different phases

Case studies in action: Critical insights on how it can go wrong

Through our decades of experience operating in and decommissioning power plants, we’ve accumulated insights about how and where projects can go off track.

Lack of full-scope safety governance

In one example, SITEX was brought into a project in which a previous vendor conducted a minimal EPA inspection. The site was confirmed EPA compliant, but in a critical oversight, the worksite still wasn’t OSHA compliant for people doing work. The vendor failed to account for the full scope of the project, causing a costly delay.

Contractors and vendors can be focused on their own objectives and individual responsibilities, which means your project needs a governance structure that ensures compliance across the work of many different groups.

Why cost can’t be your guiding factor

We know budgets are often tight and cost control is a common factor in bid selection, but the right due diligence includes knowing what measures are worth the investment.

In one case, a company wanted to demo a boiler but opted against paying for an asbestos inspection prior to the work. Barely into the job, asbestos was discovered within the boiler. Now exposed, remediation work was necessary. Furthermore, the demo crew, uncomfortable with the working environment, walked off the project. Project costs skyrocketed. By skipping a $2,000 inspection, the company faced an unexpected $30,000 remediation project and lost time.

Focusing on cost alone for project planning can easily backfire when savings are eroded by additional or unexpected back-end costs and time lost. Expert EHS governance can help avoid unnecessary budget overruns.

SITEX expertise and experience mitigate project disruption

With over 20 years of working inside power plants, SITEX has accumulated expertise that’s crucial when the time comes to decommission or demolish them. This experience allows us to speak the language of engineers and planners, assuring that comms and reports are valuable and include technically sound information.

SITEX executes a tested, standardized approach to help decommission projects safely achieve their scope of work by delivering key compliance and assessment tasks such as:

- Demolition surveys

- Comprehensive plant inspections

- Qualification of on-site contractors to attest required certifications and training

- Safety analysis audits

- Oversight of contractors for remediation/abatement jobs

- EHS cost tracking and budget management

- Emergency response prep and planning

- Complete turnkey remediation

- Safety/rescue during demolition

The complexities and dangers of coal plant decommission and demolition projects demand experience and knowledge that’s up to the task. Anything less opens the door to legal liabilities, cost overruns, and timeline disruptions. Speak to an expert at SITEX before or during the planning phase of your project.

For more details on SITEX’s energy industry expertise, check out our case study From Day-to-Day to Decommissioning to Demolition: How SITEX Turned Partnership into Power Plant Proficiency.