The Centers for Disease Control (CDC) estimates that more than 20 million workers are exposed annually to potentially damaging noise levels at work. Further research tells us that workplaces with effective hearing conservation programs have lower incidences of absenteeism and higher levels of worker productivity. So, as an employer, what are your requirements to meet OSHA noise standards and how can you maintain the safest, most productive workplace for your staff? This article will answer the following questions about noise monitoring:

OSHA has separate occupational noise standards (29 CFR 1910) for general industry and construction. The primary difference is that the Construction Noise Standard has no specific permissible exposure limit (PEL) or action level. Meanwhile, the General Industry Noise Standard requires employers to implement a hearing conservation program when the 8-hour time-weighted average (TWA) exposure is at or above 85 decibels.

Importantly, both standards emphasize the importance of conducting noise assessments (via noise monitoring), implementing controls to reduce potentially harmful noise exposure, educating workers about noise hazards, and providing the appropriate personal hearing protection (PPE) when necessary.

When exposures are at or above 85 dB, noise monitoring must be conducted. Levels above 85dB also trigger the need for a mandatory hearing conservation program. Determining the time-weighted average exposure for your location requires noise monitoring, which can be conducted by two means, often in combination.

Specific area monitoring is done by using gold-standard noise monitoring systems to record representative samples of sound level exposures at workstations within a defined area. This procedure does not account for worker mobility (i.e. workers entering and leaving the area).

For employees who are mobile throughout their shift or face fluctuating noise levels, personal noise monitoring uses attached dosimeters to measure and summarize the workers’ exposure over the course of an entire shift.

While both specific area monitoring and personal noise monitoring are useful, a customized plan specific to your worksite that incorporates a combination of the two is important to avoid any gaps in compliance, especially when a person’s exposure varies throughout a shift.

Whichever method you choose, you must figure the TWA to determine whether it exceeds the 85dB action level in the OSHA standard. If it does, you must implement a hearing conservation program.

A hearing conservation program is a set of implementations to prevent occupational hearing loss, preserve hearing, and provide workers with training/education and necessary hearing protection.

In a hearing conservation program, employers are required to:

A thorough hearing conservation program will attack harmful exposure in two different ways: engineering controls and administrative controls.

Engineering controls involve physical changes at the noise source, such as modifying or replacing equipment, or making changes along the sound transmission path to reduce noise levels near the employee’s ear. Example engineering controls include:

Administrative controls affect schedules or tasks that reduce exposure to noise. Example administrative controls include:

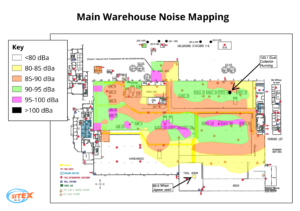

A noise map, sometimes referred to as a “noise heatmap,” is not a specific OSHA requirement. That said, this “heatmap” of your worksite or facility’s noise can be an integral part of education and controls to protect workers from exposure, especially when your site requires a hearing conservation program.

The noise map is a visual representation of sound pressure levels throughout an area. It typically uses colors and contours to indicate safer to more dangerous areas and can be critical for understanding which areas require workers to use personal protective equipment.

Noise maps can also demonstrate to OSHA your clear intentions to maintain proper noise protection compliance in the context of an investigation or inspection.

The only way to guarantee your loud worksites are compliant is through proper noise monitoring and adherence to the guidelines for hearing conservation programs. Initial monitoring can establish baseline benchmarks for your noise output. Noise heatmaps offer workers the information they need to appropriately protect themselves in certain dangerous areas.

It’s important to remember that anytime conditions for workers change, such as new equipment that produces noise at a different level, or changes to the proximity of noise for workers, you must conduct noise monitoring to confirm the new exposure levels.

In recent years, a number of smartphone apps have hit the market claiming to offer accurate sound level measurement. While the apps are convenient, there are several things to consider before relying on them for your industrial noise control plan.

Several studies have indicated wide variations in accuracy of the apps when compared to gold-standard noise monitoring systems. Furthermore, even accurate, momentary measurements are only one piece of the completed puzzle. Industrial noise control requires an understanding of noise mapping and proper noise monitoring to ensure every employee is within OSHA’s permissible exposure limit at all times.

SITEX understands the intricacies of accurate noise monitoring that keeps companies compliant and keeps workers safe. Use the form to contact one of our experts today about a plan for your industrial noise monitoring and mapping.