Combustible dust explosions are a danger in many industries, including pharmaceuticals, metal fabrication, and food or chemical manufacturing. This article provides a guide to understanding combustible dust hazards, compliance regulations related to combustible dust, the benefits of conducting a dust hazard analysis (DHA), and implementing safety measures to protect your facility and employees.

Dust is a by-product in many industries, and many forms of dust can be surprisingly flammable. A dust hazard analysis evaluates areas where combustible dusts exist, may accumulate, or be generated, and assesses the likelihood and potential severity of flash fire or explosion incidents.

In many cases, a DHA is part of a larger air quality analysis. Anytime visible dust is present, companies should assess all current and potential impacts. Other common circumstances that can create the need for a DHA include:

Any company that creates dust should address it, and a DHA may be part of that. Because newsworthy dust explosions are infrequent, combustible dust analyses tend to fall out of sight, out of mind, but Bob Hill, Sr. Project Manager at SITEX insists that doesn’t mean it should be ignored.

“When an explosion does occur, our phones are ringing off the hook because people are thinking about it again,” Hill said. “The fact is, anybody who makes any kind of dust, whether it’s coal dust, metal shavings, wheat, or plastic kerf, if it’s fine enough dust and it’s in the air, if it’s in a confined space and dense enough, it can be explosive, and you need to eliminate those hazards.”

Because combustible dust is a safety issue, there are regulations and standards related to it. Let’s take a quick look at those.

Compliance is essential for safety and legal reasons. Here are the primary regulations associated with combustible dust

The National Fire Protection Association provides guidelines for identifying and managing combustible dust hazards. These standards are not in themselves actual law, but they are often incorporated into local fire codes.

The two standards applicable here are NFPA 652 and NFPA 654, which stipulate that a dust hazard analysis is required in the following situations:

Facilities that handle, process, or generate combustible dust must conduct a DHA every five years.

Any new processes or facilities that involve combustible dust must have a DHA conducted as part of the design and commissioning process to ensure all potential hazards are identified and mitigated before operations begin.

f there are significant changes to existing processes, equipment, or facilities that could impact the dust hazard profile, a new DHA must be performed. This includes changes in production rates, the introduction of new materials, or modifications to dust collection and ventilation systems.

While OSHA does not have a specific standard for combustible dust, it enforces safety through the General Duty Clause and other related standards.

It’s also worth noting that in January 2023, OSHA issued a revised National Emphasis Program for workplaces that generate or handle combustible dusts. This program was influenced by an analysis of 2,553 inspections between 2013 and 2017 in which the agency found 3,389 combustible dust violations.

The revised NEP advises CSHOs to pay particular attention to the hazards found under the NEP and to verify that these have been addressed.

“Realistically, for any business that creates any kind of fine dust, they may not have a combustible dust situation,” Hill noted. “But it’s great to have documentation when OSHA shows up that demonstrates, ‘Yes, we’ve thought about this dust, we’ve tested it, and here’s our documented circumstances. Here’s our analysis of airborne concentrations, which are below posing any hazard.’ That piece of paper is worth a million dollars when OSHA shows up at the door.”

Understanding the nature of combustible dust, how it forms, and the conditions that allow it to ignite is essential for any facility that handles or processes dust-generating materials.

Combustible dust can be generated in virtually any industry that processes solid materials. When these materials are cut, ground, conveyed, or handled, they can release microscopic particles into the air or onto surfaces. If these particles are combustible, they can fuel a deflagration or explosion under the right circumstances.

Some of the most common sources include:

Everyday items like flour, sugar, wood, grain, cocoa, and starches can all produce combustible dust. These are especially common in food processing, agriculture, and woodworking operations.

Fine dust from aluminum, magnesium, titanium, and zinc is highly reactive and particularly dangerous. These are frequently encountered in metal fabrication, aerospace, and additive manufacturing.

Pharmaceutical powders, plastic resins, dyes, and other synthetic compounds can also generate explosive dust, particularly in chemical manufacturing, pharmaceutical production, and plastics facilities.

Even materials not typically considered “flammable” can become hazardous in dust form due to the increased surface area and dispersion potential.

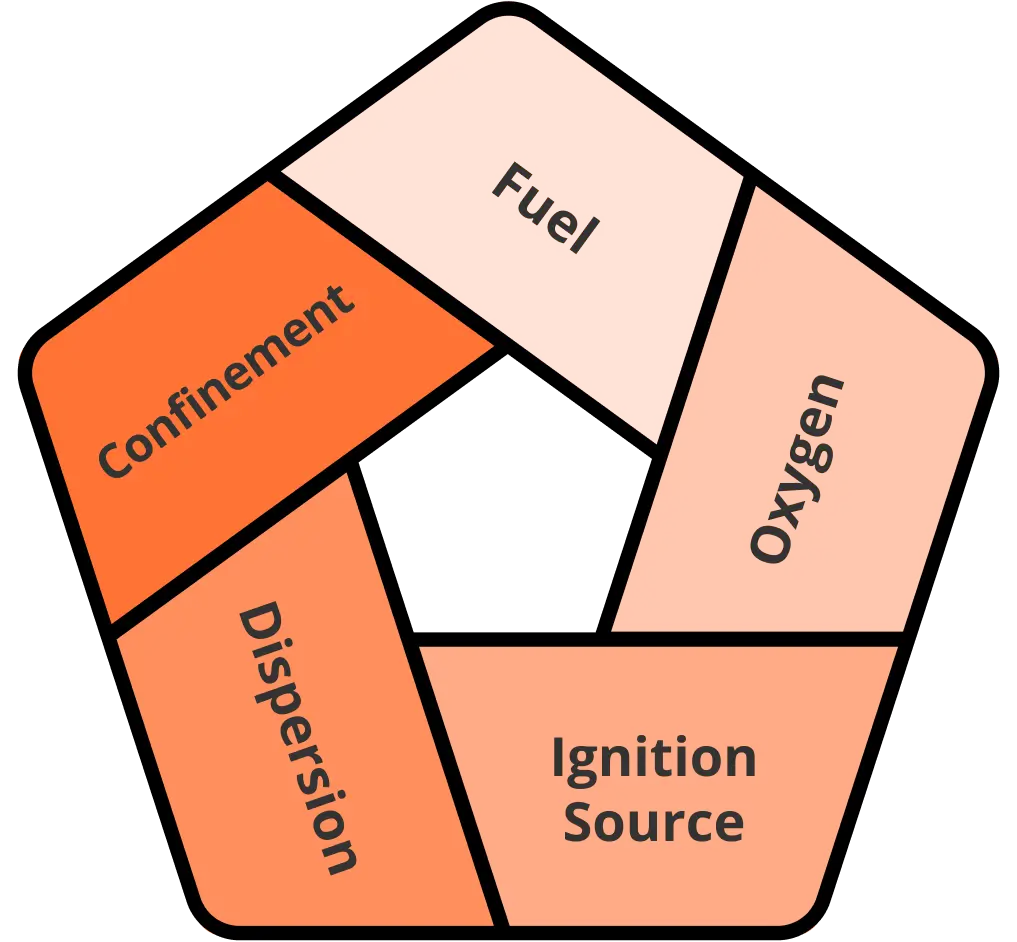

You may already be familiar with the fire triangle. The explosion pentagon model adds two critical components—dispersion and confinement—that are essential for a dust explosion to happen.

For a dust explosion to occur, all five elements must be present:

Fuel: This is the combustible dust itself, which must be finely divided and dry enough to ignite and burn quickly.

Oxygen: Typically present in ambient air; oxygen supports combustion once ignition occurs.

Ignition Source: This could be sparks, hot surfaces, friction, electrostatic discharge, open flames, or even overheated equipment.

Dispersion: Dust must be suspended in the air at a sufficient concentration to propagate a flame front.

Confinement: Enclosed or semi-enclosed environments (such as ductwork, silos, or processing rooms) can cause pressure to build rapidly during ignition, leading to an explosion rather than a flash fire.

If any one of these elements is missing, a dust explosion will not occur, which is why simple “housekeeping” measures are a good first step to preventing dust explosions. For example, good ventilation and dust collection systems can prevent dust dispersion, while removing ignition sources through grounding and bonding helps interrupt the explosion chain.

By definition, a dust hazard analysis is a systematic review that identifies potential fire, flash fire, and explosion hazards associated with combustible dusts in a facility.

Conducting a DHA is not just a regulatory requirement but a proactive step towards ensuring workplace safety. Unfortunately, a full DHA is difficult for a company to execute in-house because of the detailed sampling procedures. This can cause some companies to avoid an analysis, but that opens the door to risk.

“I had a client prior to joining SITEX, where we recommended a dust hazard analysis,” Hill recalled. “We urged them, but they declined because they didn’t think it was necessary. Eventually, they did suffer a silo explosion that, fortunately, didn’t kill any people, but did kill some animals.”

A dust hazard analysis is more than a checklist. It’s a detailed, systematic evaluation of a facility’s dust-related risks. An effective DHA entails:

Before any meaningful hazard assessment can begin, it’s essential to determine whether the dust in question is combustible—and if so, how hazardous it is under the specific conditions in which it is generated and handled.

This typically involves laboratory testing of collected dust samples to evaluate key physical and chemical properties, including:

Additional factors such as particle size, moisture content, and bulk density are also analyzed because they influence ignition sensitivity and dispersion behavior.

This step involves a thorough walkthrough of the facility, focusing on material handling processes, equipment design, and workflow dynamics. Key activities in this step include:

Data from the facility review is used to identify specific zones where combustible dust hazards are likely to occur. These might include:

Assessments of these areas should evaluate:

This stage often involves generating a hazard map of the facility, highlighting critical areas that need attention.

With those areas identified, the analysis next needs to determine the likelihood and consequence of a deflagration or explosion occurring within each hazard zone. Factors considered include:

To aid prioritization, the assessment may incorporate a risk matrix that plots severity against likelihood, guiding which areas require more immediate mitigation.

What protective measures, engineering and administrative controls, are currently in place? Is there:

At this stage, any gaps between existing protections and NFPA 652 guidelines are highlighted for remediation.

Findings from the previous steps will expose targeted corrective actions designed to close the identified gaps and minimize risks. Common recommendations include:

Each recommended action should be prioritized based on hazard potential

NFPA 652 requires documentation of the DHA process in a formal report that must be maintained and accessible to demonstrate compliance. A proper report typically includes:

It’s easy to think of a DHA as a one-and-done exercise, but as we mentioned previously, it must be revisited at least every five years, or sooner if there are significant changes. Regular review ensures that the analysis remains relevant and effective as operations evolve and new risks emerge.

Once combustible dust hazards are identified through a DHA, an industrial hygienist works to recommend and implement mitigation strategies using engineering and administrative controls.

These aim to eliminate the hazard at the source or isolate it from workers and processes, and include:

These reduce the risk by modifying how people interact with processes. General administrative controls include:

Understanding past incidents can highlight the importance of proper dust hazard management. Two such examples include the Imperial Sugar refinery explosion in 2008 and the West Fertilizer explosion in 2013.

|

Imperial Sugar Refinery Explosion (2008) In this incident, sugar dust accumulation caused a massive explosion, resulting in 14 deaths and numerous injuries. Investigations revealed inadequate housekeeping and dust control measures. This explosion played a major role in OSHA’s Combustible Dust National Emphasis Program and spurred the NFPA to strengthen NFPA 652. |

West Fertilizer Explosion and Fire (2013) This mammoth explosion at a fertilizer storage and distribution facility fatally injured 15 and injured dozens more. The Chemical Safety Board investigation found poor hazard awareness to be a major factor in the incident. |

By understanding and addressing combustible dust hazards through a comprehensive DHA, facilities can create a safer work environment, prevent catastrophic incidents, and stay compliant with regulations.

SITEX has expertise in conducting DHAs and implementing corrective measures, but also recognizes that not all dust accumulations warrant a full dust hazard analysis.

“We don’t just immediately jump into a DHA unless we know you need it,” Hill noted. “The way we look at it is, let’s test the dust first to find out if it’s explosive. If it is, let’s see how much there is. Next, let’s see how much is actually in the air. If you have enough where you have a potentially explosive situation, then you should have a full-blown DHA where we’re looking deeper into processes, potential ignition sources, and control gaps.”

As a dedicated safety partner to our clients, we prioritize safety and compliance, but we also recognize the reality of budgets and costs associated with safety and industrial hygiene, so we ensure the need for a service before recommending it.

“We once tested a chemical facility and found dust that was indeed combustible, but only at a certain concentration. And in order to hit that concentration, the plant wouldn’t even be inhabitable for workers because there would be so much of the dust that workers couldn’t breathe,” Hill explained. “So we explained that a full DHA wasn’t necessary, but here are our recommendations for housekeeping and administrative controls that will keep the facility safe and compliant.”

Complete the form on the page to contact us about combustible dust hazard analysis and testing.